I am going to give you a synopsis of a paper I did in Shanghai just before Christmas, and I called it Cargo Transport 2020 to 2050 because in the end whatever else it is about, I mean our business is moving cargo, we love ships, we are very interested in ships, they are what we use, but it really is about how we develop our cargo.

I should have finished 15 minutes ago, so in Yuri’s interest I am going to skid through. However, you can find the slides that I would have given you, I have sort of cut it down a great deal, on the enrolling student’s Naval Architects website, I am just putting it up at the moment. So, if you want to go, that is okay, you can see it on the web.

The things I want to do, is first of all talk about where we are now, very briefly.

Secondly, a bit about the impact of climate change which I hope will complement what we have heard already, the cargo transport systems and then the technology, and I think that in a way the technology is the one thing that we have got very solidly in front of us, that we can do and ought to do, and that is really where I want to get to, the climate change is a little bit different.

So, let me start with where we are now. Basically, I would say that we are at the peak of a great fossil fuel cycle which started about 150 years ago and I think that, because we are at the peak, what lies ahead is going to be very different. If we just go back to the last time shipping was a truly green industry, that was about 1840, we moved 20,000,000 tons of cargo with 30,000 ships, and those ships were the result of 300 years of refining naval architecture, they were extremely efficient, most of them were under 200 tons, and if we fast forward to last year, the diesel engine I think was a very big step forward, it appeared in the 1950s and last year we moved 12 billion tons of cargo with 60,000 ships and that was made possible by fossil fuels.

You would have needed literally millions of sailing ships to move what we moved last year without the power of fossil fuels. I guess that the amazing thing is not just fossil fuels, the truly amazing thing is oil; you pump, you drill a hole in the ground and out comes oil, Saudi Arabia still costs not much more than a dollar a barrel. It is absolutely packed with energy. Not only that, you can pump it round the ship, it is perfect from the naval architect’s point of view, I mean the change from coal to oil was wonderful, you had 30 people in the engine room stocking boilers with coal, and suddenly you can put the oil in a tank and a double bottom wherever it is and it is out of the way.

So, the elephant in the room is basically this great beast, this is the MMSC engine, it develops 109,000 HP. That probably does not mean much to most of you, so let’s say that if people were doing the work of this engine, you would need 3 million of them, they would be working eight-hour shifts, 3 million people, and they would need a town the size of Athens to sleep in, they would actually eat 3 billion calories a day, so, unlike oil, you cannot stick them in a double bottom, you would have a fleet of ships serving the ship. Every ton of oil burnt produces 3.3 tons of carbon.

Now, where we sit on this, I do not know, maybe the Arctic is floating, I haven’t heard that one before, that was a great statistic. I am now hoping my house in London might be a prime waterfront property soon, because I am at the top of the hill, so I am okay, but I think the elephant in the room is that, and I think the one thing, if you have got to say one thing about it, replacing it is not going to be cheap, it is not going to be a dollar a barrel, you know, if you say it is three times as much, it would not surprise me, if it says it costs five times as much to run the ships, it would not surprise me.

So, I think what this does, I mean climate change is just another step along the fossil fuel road. When I started working in 1970, we were worried about running out of oil, and indeed, there were very good reasons to believe that, we went to winter in London, where there is no central heating in the offices and there was a shortage of commodities. So, I think that we have to see this as part of a process and I think it is the peaking out now, we have reached the point where we have to look at something else. It seems to me that one of the most telling statistics about the shipping industry is that we do not measure our performance. This is the tons of cargo moved for dead-weight ton of shipping capacity since 1963, and it has not changed at all. It is a bit lower today, it went down in the Great Depression of the 1980s, when ships were slow and waiting all the time. It has gone down in the last five or ten years because ships have slowed down, because of slow steaming, high bunker prices and, of course, it is environmentally helpful as well.

As an industry we are not used to measuring our performance, and one of the reasons we do not do that is that we really do not have the technology to do it, or we did not have the technology to do it, but I think that not only do we have the technology to do it now, but we are going to the whole, the process of regulation which is what drove the car industry 30 years ago, is going to force us to measure performance, I mean I am supposed to be recording how much carbon our ships produce but the companies that I have worked with have no idea how much carbon their ships produce, not proper statistics, they can give you bunker bills, but not how much carbon they produce.

So, what I am going to suggest is that this chart shows you, basically the blue line is carbon emissions by ships, so there we go, this is there, and this is million tons of CO2 emissions per year. This is what happens if we go on building ships the way we do it at the moment and operating them the way we are, and trade grows at 3.2% per annum as it has done in the last 50 years. I have to say that a consistent theme with the previous two speakers is an expectation we are going to continue to grow, and if we do that, then I do not know what IMO is going to do. That is what IMO has told us we have got to do, the red dot. That is what it says. Anybody disagree with that? For about 450,000,000-470,000,000 tons of emissions in 2050, and we are supposed to grow trade and carry anything that is going to be carried on the seas. Ok, that is what we have got to do. This is how you can do it. You can actually get that quite easily. First thing you do is that you move less cargo. Freight has been cheap as chips for the last 50 years, you move stuff without even thinking about it, we need to think about it, that is the first thing.

The second thing is that we need to slow down. For 30 or 40 years, when you had to shovel coal into boilers, ships were designed for 10 knots, they were not designed for 14 knots, and they went fine.

Zero carbon power is problematic; we have not got anything to replace oil, except nuclear, maybe nuclear will solve the problem, I mean, you know, one of the most amazing things of the LED light bulbs which use no electricity at all compared with the old ones, and maybe we can find some sort of technology like that, but there is not nothing on the table, the best bet seems to be fuel cells and some sort of green hydrogen for the 2030s, but it is not a very convincing story for deep sea, short sea is a bit easier.

Then, of course, to do all this we need to think about our 3,000 year old personnel system, which again was mentioned earlier, and the problem with getting people to sea today etc.

Just to run that through in numbers, if we slow down, if we cut cargo growth to 2.2% per annum, we get down to 1.8 billion tons. If we slow down to 10 knots and cut cargo to 2.2% growth, we get down to about 800,000 tons, and that just leaves the last bit, which is the zero carbon part, but we get a lot of the way. The thing is we can get a lot of the way there by doing things we can do, that is the point.

The technology only takes us to the last lap of the race, that is the point I am trying to make.

As far as the transport scenario is concerned, there is just a couple of questions that I would like to sort of raise. This is the sea-borne trade and the growth to 12 billion tons, where we are today, and there are two questions here. The first is, we have grown 27% since the credit crisis. You know, where did it go? I mean, literally, within ten years we have grown 27%. Why? Has it really added that much to society? There are people who are not in this room, who are growing the trade at the moment. The second thing is that 37% of our trade with fossil fuels, what is that going to be in 2050? Well, if the rest of the world does their jobs, it could be nothing. If the cars stop using oil and we all go to a green car, in which case trade will go down very substantially. I have just listed on the other side of this chart the things you can do to slow down trade, I think it is quite a reasonable thing to look at.

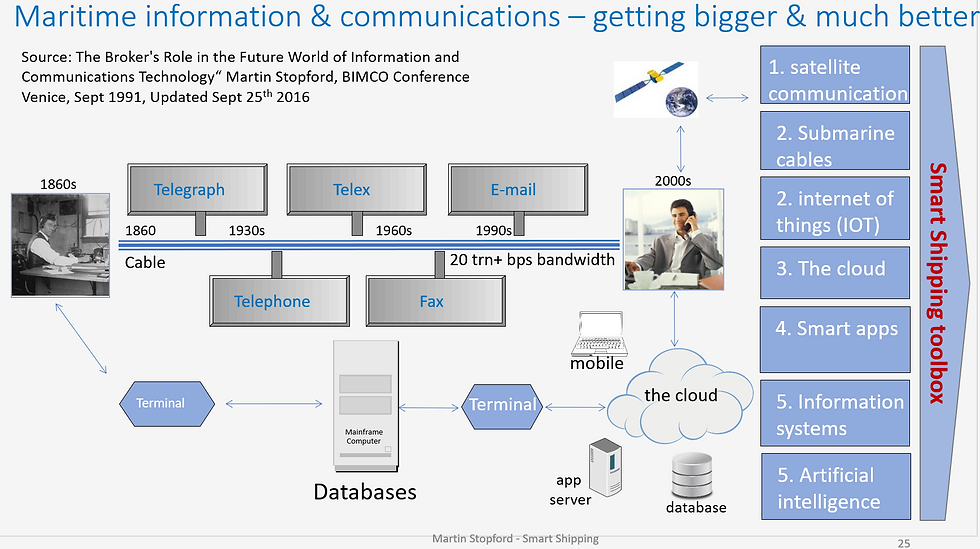

We have got new technology, and I think this is the most interesting part, and in a way it is the thing I have been looking at for about six or seven years; I could never see quite what was the hook that was going get us to use this new digital technology, but actually climate change is a very good hook to get us down that road. What we have got is two converging trends at the moment; we have got very long converging trends in the communication area which started, the development of communications in shipping is as old as the hills, it started in 1860, Clarksons was built on the cable network in London, that is how Horace Clarkson got started, and we have added the cloud, we have got some much-much better satellites and they are getting better and better, and we have got a whole bunch of new technology coming in from the other parallel development which has been going on, which is computers.

Actually, the first commercial computer was this one here, this was 1951, called Leo, it had 8k of memory, I mean my presentation is about 50MB or something. Then, the 1960s, 6600 super-computer, this had about 1MB of memory, and it was all stored on this thing. This was our first computer programmed in 1969. Then, today though, we have this, it is cheap as chips, it costs nothing, you go buy, you can buy, this is massively powerful, I7 processor, 8 cores, 12MB cache, 393 dollars from Google. This is a thing, this is a little kit for 9 dollars a month. You plug that into the OBD plug on your car, and you can figure out what your children are doing, and how fast they are driving and where they are, and whether your aging parent has collapsed at the wheel. All of this stuff and it costs 9 dollars a month.

You know, this is not new technology, this is there today, it is just that it is a bit trickier to predict to working ships, but the cars have done it. I mean, in 1967 cars were full of wires, you stuffed these wires behind the dashboard and, of course, they all came off, and the lights did not work and things like that. Well, what changed that was the regulators, the Californian regulators in the 1980s said they wanted proper evidence of fuel consumption, they wanted to tap straight into the engine, and in 1983 Boston Intel came up with the CANbus system for basically removing the wiring from cars and putting it all into a network, and today’s car, the Economist described a BMW as a computer on wheels, and it set it up, they are all ready for the electric car, they have got the onboard systems to do it, you could not describe the average ship today as a computer on wheels, I mean, to be honest, it is very similar to the ships we were building, or the Japanese were building, when I was in ship building in the 1980s, you know, they have not really changed that much.

Where we should be focusing is on the onboard systems, we really need to integrate these and to start to bring them together and, interestingly, for example Sperirand have just come out with a completely integrated net marine navigation system. All the equipment involved in navigation, same system, the same screens for every part of the system, and it clings perfectly to the shore server, on shore can see exactly what the master sees. This is just common sense, it just gives you another step forward and the satellite systems are pretty well there to do it, I would say. But you cannot do it, if you are going to hardwire this stuff, you really need to put something like the CANbus system that you have in motor cars, you need to put into ships. This raises lots of problems, but the essence here is that, say Sperirand built a navigation system, it has an electronic control unit that plugs into the backbone, everything on the ship communicates through the backbone, through the CANBus, F2 is the latest version. The current protocols would need to be revised; there is a protocol NMEA 2000 for ships, but it only works for vessels up to about 50 meters.

But, incidentally, if you do that, the other side of the coin is that we have the communications now to run ships as transport factories. I am over my time, so I am not going to dwell on explaining all of this, but the Minister mentioned the problems with the crew and so forth, and really, if we do not do something about that, it is a problem that needs to be solved. I think we need to go from the vertical system to a more horizontal system of management and, of course, this is going to change the way offices are managed on shore and the way that the onboard management is structured, and indeed, the way that the ships communicate with the regulators, the classification societies, equipment suppliers, customers, and ports, all of this is there waiting to happen.

From an investment point of view, it is a major challenge, because, unfortunately, if you have a vision of the sort of ships I have been describing, how you are going to depreciate the ship you order tomorrow in Japan, it is a big issue, and I think my answer to that is that it is all going to take a long time. If you look at it, it took 70 years to get from the first decent steam ship to actually a fleet of steam ships, and I think the same thing is going to happen, we need to start off by fine-tuning the emissions on existing designs and putting in the sort of digital engineering that we can put in and retrofit as quickly as possible, and there is an awful lot of that, and then we move on to maybe some intermediate stuff, like gas batteries, whatever is the flavour of the month, which has got a better carbon footprint and, finally, step 3, the electric ships, which gets us down to the IMO target in 2047.

But very finally, just to mention a few of the things you can do today, and I apologise, Yuri, I have not been with my 15 minutes, Yuri here is tearing his hair out, but once you are up here, you know, it is the one moment you are in control, until they switch the projector off.

Practical digital training programs. I think the sooner you get people who understand digital technology and are happy with it into your middle management of shipping and on ships, the better.

It does not matter what you do, you just start doing it, because it is the only way, I mean, I have been managing teams and digital people all my life and the only way you get started is you get someone started, it does not work to begin with, but eventually you have got the knowledge and the critical mass to do it, and there are a few shipping companies doing some very good stuff with this.

The second thing is remote underwater examination with robotic crawlers, there is plenty of them around. Digital information about corrosion. Fantastic, you know, whereas currently you put a surveyor on the ship and he goes around and produces a great load of paper about the corrosion condition in the hull, you take photographs, scan them and send them back to some boffins who will then run algorithms and show you, and they will analyse the exact levels of corrosion and categorize them and digitalize them. Anybody who has used modern things like Capture One photo editing software will know exactly this sort of thing, this stuff is very clever now, and it is just quicker, you get rid of these loads of paper and you get much-much more usable data later, and it all goes eventually into your digital twin ship which maybe you are keeping or maybe the cluster side is keeping for you. So, you have got a different sort of records.

E-certificates is a good one, a lot of people are doing that.

Image analytics, coatings, corrosion, cracks, if you have a collision, photographs can then be analysed.

Dashboards and timeseries. Timeseries is very important, because if you keep timeseries, you can do anomaly correction, so you actually, instead of waiting for some bit of equipment to break down, you analyse timeseries and you start to get little algorithms which will tell you, which will start to predict that you might have problems in that bit of equipment. Again, these things are stuff you can do as soon as you like, it is sort of coming along.

Monitoring operational efficiency with data, deep learning algorithms. It is getting better, I mean, I am astonished how better stuff has gotten just very recently, and I think the whole point about measuring the performance of our ships, our carbon footprint on the cargo we transport, so many things, we are at the position where you can do it, it is a lot of work and it needs a different sort of organization structure to do that.

I am not going to go through the conclusions, because I think I have covered the main points I wanted to make, but I think that is the end, you will be glad to hear Yuri and thanks very much for your attention.

Martin Stopford is a graduate of Oxford University and has a PhD in International Economics from London University. During his 45 years in the Maritime Industry he has held positions as Director of Business Development at British Shipbuilders; Global Shipping Economist with Chase Manhattan Bank N.A.; Chief Executive of Lloyds Maritime Information Services and an executive director of Clarksons PLC. He retired from Clarksons in May 2012 and is now non-executive President of Clarkson Research Services Limited (CRSL) and Director of MarEcon Ltd, his e-learning business.

Dr Stopford is a visiting Professor at Cass Business School in London, Dalian Maritime University in China and Newcastle University. He has an Honorary Doctorate from Solent University. He has received several awards, including a lifetime achievement award from Lloyds List in 2010; Shipping Personality of the Year at the Seatrade Global Awards Dinner in 2013; the Onassis Prize for Shipping in 2015; and the Capital Link Shipping Leadership Award in New York in 2016.

His publications include “Maritime Economics” 3rd Ed, the widely used shipping text book published in January 2009, and many papers on shipping economics and shipping finance.

Professor Martin Stopford's full speech:

Professor Martin Stopford's presentation titled "CARGO TRANSPORT 2020 to 2050 - The 4th sea transport revolution":

MareGreco.com A proud media partner of the

Comments